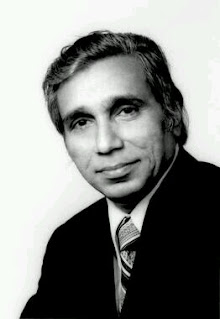

Fazlur Rahman Khan (Bengali: ফজলুর রহমান খান, Fozlur Rôhman Khan) (3 April 1929 – 27 March 1982) was a Bangladeshi-American structural engineer and architect who initiated important structural systems for skyscrapers. Considered the "father of tubular designs" for high-rises, Khan was also a pioneer in computer-aided design (CAD). He was the designer of the Sears Tower (now Willis Tower), the tallest building in the world until 1998 and the 100-story John Hancock Center.

Khan, more than any other individual, ushered in a renaissance in skyscraper construction during the second half of the 20th century. He has been called the "Einstein of structural engineering" and the "Greatest Structural Engineer of the 20th Century" for his innovative use of structural systems that remain fundamental to modern skyscraper construction. The Council on Tall Buildings and Urban Habitat established the Fazlur R. Khan lifetime achievement medal in his honor.

Although best known for skyscrapers, Khan was also an active designer of other kinds of structures, including the Hajj airport terminal, the McMath–Pierce solar telescope, and several stadium structures.

Biography

Fazlur Rahman Khan was born 3 April 1929 in Dhaka in the Bengal province of British India (Dhaka became part of Pakistan after 1947 and now Bangladesh since 1971). He was brought up in the village of Bhandarikandii, in the Faridpur district near Dhaka. His father Abdur was a high school mathematics teacher and textbook author. He eventually became the Director of Public Instruction in the region of Bengal and after retirement served as Principal of Jagannath College, Dhaka.

Khan attended Armanitola Government High School, in Dhaka. After that, he studied Civil Engineering in Bengal Engineering College Shibpur in India and ultimately received his Bachelor of Civil Engineering degree from Ahsanullah Engineering College, University of Dhaka, (now Bangladesh University of Engineering and Technology). He received a Fulbright Scholarship and a Pakistan government scholarship, which enabled him to travel to the United States in 1952. There he studied at the University of Illinois at Urbana-Champaign. In three years Khan earned two master's degrees — one in structural engineering and one in theoretical and applied mechanics — and a PhD in structural engineering. with thesis titled Analytical study of relations among various design criteria for rectangular prestressed concrete beams.

Career

A sculpture of Khan at the Willis Tower

Khan introduced design methods and concepts for efficient use of material in building architecture. His first building to employ the tube structure was Chestnut De-Witt apartment building.

In 1955, employed by Skidmore, Owings and Merrill, he began working in Chicago, Illinois, United States. He was made a partner in 1966 and became a naturalized American citizen in 1967. During the 1960s and 1970s, he became noted for his designs for Chicago's 100-story John Hancock Center and 110-story Sears Tower, the tallest building in the world in its time.

He believed that engineers needed a broader perspective on life, saying, "The technical man must not be lost in his own technology; he must be able to appreciate life, and life is art, drama, music, and most importantly, people."

Khan's personal papers, the majority of which were in his office at the time of his death, are held by the Ryerson & Burnham Libraries at the Art Institute of Chicago. The Fazlur Khan Collection includes manuscripts, sketches, audio cassette tapes, slides and other materials regarding his work. The International Association for Life Cycle Civil Engineering named their Life-Cycle Civil Engineering Medal after Khan.

Innovations

Khan discovered that the rigid steel frame structure that had dominated tall building design and construction so long was not the only system fitting for tall buildings, marking the beginning of a new era of skyscraper construction.

Tube structural systems

Khan's central innovation in skyscraper design and construction was the idea of the "tube" structural system for tall buildings, including the "framed tube", "trussed tube" and "bundled tube" variations. His "tube concept," using all the exterior wall perimeter structure of a building to simulate a thin-walled tube, revolutionized tall building design. Most buildings over 40-stories constructed since the 1960s now use a tube design derived from Khan's structural engineering principles.

The tubular designs are for resisting lateral loads (horizontal forces) such as wind forces, seismic forces, etc. The primary important role of structural system for tall Buildings is to resist lateral loads. The lateral loads begin to dominate the structural system and take on increasing importance in the overall building system when the building height increases. Forces of winds become very substantial and forces of earthquake etc. are very important as well. It is the tubular designs that are used for tall buildings to resist such forces. Tube structures are very stiff and have numerous significant advantages over other framing systems. They not only make the buildings structurally stronger and more efficient, they significantly reduce the usage of materials while simultaneously allowing buildings to reach even greater heights. The reduction of material makes the buildings economically much more efficient and reduces environmental issues as it results in the least carbon emission impact on the environment. Tubular systems allow greater interior space and further enable buildings to take on various shapes, offering unprecedented freedom to architects. These new designs opened an economic door for contractors, engineers, architects, and investors, providing vast amounts of real estate space on minimal plots of land. Khan was among a group of engineers who encouraged a rebirth in skyscrapers construction after a hiatus for over thirty years.

The tubular systems have yet to reach their limit when it comes to height. Another important feature of the tubular systems is that buildings can be constructed using steel or reinforced concrete, or a composite of the two to reach greater heights. Khan pioneered the use of lightweight concrete for high-rise buildings, at a time when reinforced concrete was utilized primarily for low-rise construction of only a few stories in height.Most of Khan's designs were conceived considering pre-fabrication and repetition of components so projects could be quickly built with minimal errors.

The population explosion, beginning with the baby boom of the 1950s, created widespread concern about the amount of available living space. Khan had the solution — building up.More than any other 20th-century engineer, Fazlur Rahman Khan made it possible for people to live, and work in “cities in the sky.” Mark Sarkisian (Director of Structural and Seismic Engineering at Skidmore, Owings & Merrill) said, "Khan was a visionary who transformed skyscrapers into sky cities while staying firmly grounded in the fundamentals of engineering."

Khan's initial projects were the 43 stories DeWitt-Chestnut (1964) and 35 stories Brunswick Building (1965). His most important projects were the John Hancock Center and the Willis Tower.

Framed tube

Since 1963, the new structural system of framed tubes became highly influential in skyscraper design and construction. Khan defined the framed tube structure as "a three dimensional space structure composed of three, four, or possibly more frames, braced frames, or shear walls, joined at or near their edges to form a vertical tube-like structural system capable of resisting lateral forces in any direction by cantilevering from the foundation." Closely spaced interconnected exterior columns form the tube. Horizontal loads, for example from wind and earthquakes, are supported by the structure as a whole. About half the exterior surface is available for windows. Framed tubes allow fewer interior columns, and so create more usable floor space. The bundled tube structure is more efficient for tall buildings, lessening the penalty for height. The structural system also allows the interior columns to be smaller and the core of the building to be free of braced frames or shear walls that use valuable floor space. Where larger openings like garage doors are required, the tube frame must be interrupted, with transfer girders used to maintain structural integrity.

The first building to apply the tube-frame construction was the DeWitt-Chestnut Apartments building that Khan designed and was completed in Chicago in 1963. This laid the foundations for the framed tube structure used in the construction of the World Trade Center.

Trussed tube and X-bracing

Khan pioneered several other variations of the tube structure design. One of these was the concept of applying X-bracing to the exterior of the tube to form a "trussed tube". X-bracing reduces the lateral load on a building by transferring the load into the exterior columns, and the reduced need for interior columns provides a greater usable floor space. Khan first employed exterior X-bracing on his design of the John Hancock Center in 1965, and this can be clearly seen on the building's exterior, making it an architectural icon.

In contrast to earlier steel-frame structures, such as the Empire State Building (1931), which required about 206 kilograms of steel per square meter and Chase Manhattan Bank Building (1961), which required around 275 kilograms of steel per square meter, the John Hancock Center was far more efficient, requiring only 145 kilograms of steel per square meter. The trussed tube concept was applied to many later skyscrapers, including the Onterie Center, Citigroup Center and Bank of China Tower.

Bundle tube

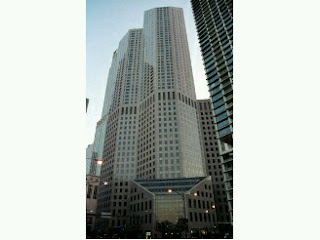

One of Khan's most important variations of the tube structure concept was the "bundled tube," which he used for the Willis Tower, One Magnificent Mile, and the Newport Tower (Jersey City). The bundle tube design was not only the most efficient in economic terms, but it was also "innovative in its potential for versatile formulation of architectural space. Efficient towers no longer had to be box-like; the tube-units could take on various shapes and could be bundled together in different sorts of groupings."

Tube in tube

Tube-in-tube system takes advantage of core shear wall tubes in addition to exterior tubes. The inner tube and outer tube work together to resist gravity loads and lateral loads and to provide additional rigidity to the structure to prevent significant deflections at the top. This design was first used in One Shell Plaza. Later buildings to utilize this structural system include the Petronas Tower.

Outrigger and belt truss

The outrigger and belt truss system is a lateral load resisting system in which the tube structure is connected to the central core wall with very stiff outriggers and belt trusses at one or more levels.BHP House was the first building to utilize this structural system followed by the US Bank Center in Milwaukee. The US Bank Center rises 601 feet, with three belt trusses at the bottom, middle and top of the building. The exposed belt trusses serve for both aesthetic and structural purposes. Later buildings to utilize this include Shanghai World Financial Center.

Concrete tube structures

The last major buildings engineered by Khan were the One Magnificent Mile and Onterie Center in Chicago, which employed his bundled tube and trussed tube system designs respectively. In contrast to his earlier buildings, which were mainly steel, his last two buildings were concrete. His earlier DeWitt-Chestnut Apartments building, built in 1963 in Chicago, was also a concrete building with a tube structure. Trump Tower in New York City is also another example that adapted this system.

Shear wall frame interaction system

Khan developed the shear wall frame interaction system for mid high-rise buildings. This structural system uses combinations of shear walls and frames designed to resist lateral forces. The first building to utilize this structural system was the 35-stories Brunswick Building.The Brunswick building was completed in 1965 and became the tallest reinforce concrete structure of its time. The structural system of Brunswick Building consists of a concrete shear wall core surrounded by an outer concrete frame of columns and spandrels.Apartment buildings up to 70 stories high have successfully utilized this concept.

Legacy

Khan's seminal work of developing tall building structural systems are still used today as the starting point when considering design options for tall buildings. Tube structures have since been used in many skyscrapers, including the construction of the World Trade Center, Aon Centre, Petronas Towers, Jin Mao Building, Bank of China Tower and most other buildings in excess of 40 stories constructed since the 1960s.The strong influence of tube structure design is also evident in the world's current tallest skyscraper, the Burj Khalifa in Dubai. According to Stephen Bayley of The Daily Telegraph:

Khan invented a new way of building tall. [...] So Fazlur Khan created the unconventional skyscraper. Reversing the logic of the steel frame, he decided that the building's external envelope could – given enough trussing, framing and bracing – be the structure itself. This made buildings even lighter. The "bundled tube" meant buildings no longer need be boxlike in appearance: they could become sculpture. Khan's amazing insight – he was name-checked by Obama in his Cairo University speech last year – changed both the economics and the morphology of supertall buildings. And it made Burj Khalifa possible: proportionately, Burj employs perhaps half the steel that conservatively supports the Empire State Building. [...] Burj Khalifa is the ultimate expression of his audacious, lightweight design philosophy.

Other architectural work

Khan designed several notable structures that are not skyscrapers. Examples include the Hajj terminal of King Abdulaziz International Airport, completed in 1981, which consists of tent-like roofs that are folded up when not in use. The terminal's structure has been made to adapt to the harsh desert conditions. The tent-like tensile structures advanced the theory and technology of fabric as a structural material and led the way to its use for other types of terminals and large spaces.[citation needed] The King Abdulaziz International Airport received several awards, including the Aga Khan Award for Architecture, which described it as an "outstanding contribution to architecture for Muslims".

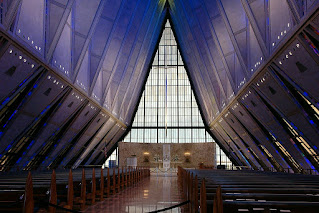

Khan also designed the King Abdulaziz University, the United States Air Force Academy in Colorado Springs and the Hubert H. Humphrey Metrodome in Minneapolis.[citation needed] With Bruce Graham, Khan developed a cable-stayed roof system for the Baxter Travenol Laboratories in Deerfield.

Khan and Mark Fintel conceived ideas of shock absorbing soft-stories, for protecting structures from abnormal loading, particularly strong earthquakes, over a long period of time. This concept was a precursor to modern seismic isolation systems.

Computers for structural engineering and architecture

In the 1970s, engineers were just beginning to use computer structural analysis on a large scale. SOM was at the center of these new developments, with undeniable contributions from Khan. Graham and Khan lobbied SOM partners to purchase a mainframe computer, a risky investment at a time when new technologies were just beginning to take shape. The partners agreed, and Khan began programming the system to calculate structural engineering equations and, later on, to develop architectural drawings.

List of buildings

Buildings on which Khan was structural engineer include:

DeWitt-Chestnut Apartments, Chicago, 1963

Brunswick Building, Chicago, 1965

John Hancock Center, Chicago, 1965–1969

One Shell Square, New Orleans, Louisiana, 1972

140 William Street (formerly BHP House), Melbourne, 1972

Sears Tower, Chicago, 1970–1973

U.S. Bank Center, Milwaukee, 1973

Hajj Terminal, King Abdulaziz International Airport, Jeddah, 1974–1980

King Abdulaziz University, Jeddah, 1977–1978

Hubert H. Humphrey Metrodome, Minneapolis, Minnesota, 1982

One Magnificent Mile, Chicago, completed 1983

Onterie Center, Chicago, completed 1986

United States Air Force Academy, Colorado Springs, Colorado

Comments

Post a Comment

If you have any doubts, Please let me know